At first glance, a flat roof might look like a simple blank canvas for a solar project, but there are many factors to consider when designing an array, from tilt angle to power curve to possible roof attachments. Fortunately, a few quick steps in planning can help you to optimize your system.

With 5 GW of solar under its belt and more than 21 years of leadership in solar, Unirac is well-positioned to provide best practices in this space. That’s why we teamed up with the Unirac Director of Customer Solutions Brandon Carrasco to share a detailed look into their approach.

Determine project goals and constraints

Step 1 in the planning process is understanding what you want from your solar installation. For example, are you looking for the best energy production per module, or does the available roof area restrict you and you need to maximize power capacity by designing for density? Depending on your project goals, you may choose one tilt angle over another, or you may design for greater module density. Similarly, buildings with many roof obstacles or with off-azimuth orientations may create a need for greater module-layout flexibility.

Once you identify the constraints and have a clear picture of where you need to get to, you will be ready to start on your design.

“One size does not fit all,” Carrasco said.

Choose a product

The next step is product selection. Note: Be sure to select a product that will keep your labor costs down. For example, Unirac’s portfolio of flat roof mounting solutions meet important labor-saving criteria including:

- Single-tool installation process.

- Minimal components to reduce complexity and save labor hours.

- Wire-management features and other aides to quick installation.

- Condensed packaging that minimizes crane hauls and storage costs.

Here is a helpful article on labor savings where you can find more thoughts.

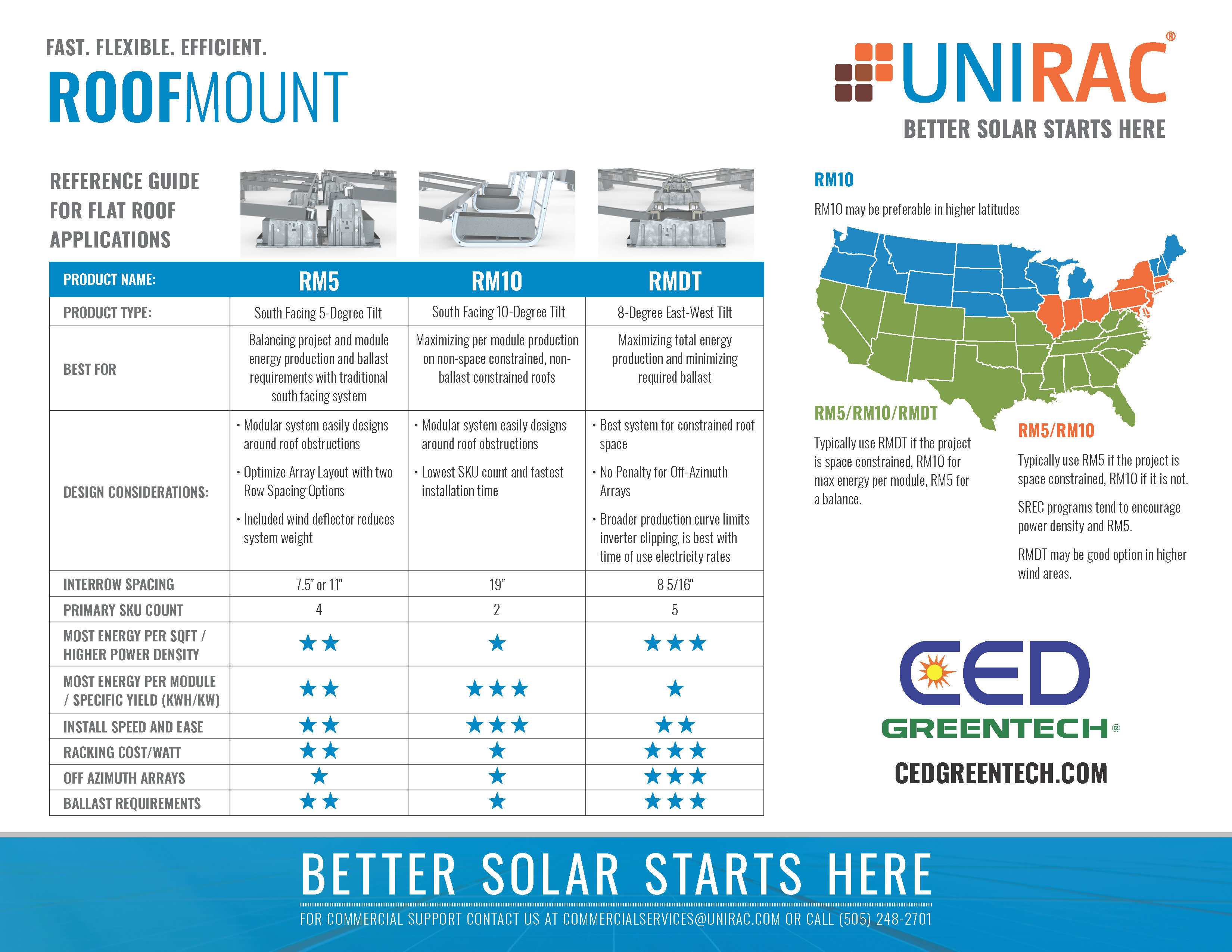

Each of the three mounting systems which comprise Unirac’s flat roof product line has unique advantages to help you optimize your array: a 5-degree tilt (RM5), a 10-degree tilt (RM10) and a dual 8-degree tilt (RMDT) sometimes referred to as “East-West.” The following are key benefits of each system. Be sure to print and keep the RM Flat Roof Reference Guide linked here as a quick design aide.

- RM5: A balance of module production and density

- Crunch the numbers—sometimes a middle-ground solution is the perfect answer. Unirac’s RM5 hits this sweet spot with just four major components (the ballast bay, module clamp, wind deflector and U-nut) and 11" and 7.5" row-spacing options that yield more modules on the roof. RM5 is an adaptable, flexible system made of marine-grade galvanized steel for durability.

- RM10: Maximize module production

- For higher module yield, look for an easy-install, affordable system. Unirac meets the need with RM10, which offers one of the easiest and fastest ballasted racking installs in the industry. It has two main components: a lightweight aluminum construction and a simple layout. RM10 is the original flat-roof ballasted product and has withstood the test of time due to its broad applications.

- RMDT: Maximize power density and minimize weight on the roof

- If you want the greatest number of modules for a given space, dual tilt (RMDT) is the clear winner, giving you 32% more modules for a given space than a south-facing 10-degree system. While RMDT still offers streamlined components (five) and simple layouts, it provides roof-coverage that cannot be matched by other methods.

- RMDT is also unique in that there is no penalty for off-azimuth building orientation, lending itself to unusual parameters. It is economical and can be especially good for very large projects.

Unirac will soon introduce a grid-style mounting system for flat roof projects with low ballast requirements.

Consider roof attachments

Is there a limit to the additional weight, or structural load, you can place on the roof? While roof attachments are a necessity in high-seismic areas due to code, they may be optimal for certain buildings to reduce the weight on the roof. Unirac’s flat roof mounting solutions are compatible with a wide variety of off-the-shelf attachments which will eliminate ballast blocks from the array and reduce the structural load. If you are unsure about the building’s structural capacity, check with the building owner or engage with your 3rd party structural engineer to evaluate the structure.

Look for a supplier committed to helping you through the process

A good manufacturer will provide a depth of service beyond simply making great products, with service designed to assist you as an installer or designer working in the commercial arena.

“We have more than two dozen people working around the clock who can help with anything that comes up,” Carrasco said. “Unirac can assist with layout comparisons, engineering, drawings, stamps and even on-roof training and problem-solving through our Installer Sales Specialists. You can also make your own designs using our free, world-class online U-Builder tool, and we have an unmatched technical support section on our website.”

Additionally, project delays can be expensive, so make sure the manufacturer can get the material to you on time and within any specific installation windows. Unirac works with trusted partners like Greentech Renewables to provide industry-leading lead times and product availability.

“This is what we’re here for—this is the full value of buying through a trusted partner,” Carrasco said. “Ready availability and a deep service bench from a company with experience in some of the largest rooftop projects out there mean that together, we can make sure your next rooftop project, big or small, is a success.”

To learn more or if you have any questions, click the button below to set up a conversation with a Greentech Renewables sales expert. Fill out the form with "Unirac info request" in the message to help us better route you!

Comments

Excellent points! Flat rooftops are an excellent canvas for PV; with that said, shortcuts should not be taken!